time:2018-10-16 author:David Carr,ADI company

With the increasing trend of electrification of cars and other means of transport, the demand for isolation is also increasing. Traditional isolation methods can not successfully cope with market demands and challenges. Fully integrated, secure and certified isolated DC-DC converter with EMC performance documentation provides a better solution for system designers.

It is undeniable that the electrical system becomes smaller and lighter, and electrification of cars is the best example. PwC, a professional services company, expects hybrid and all-electric vehicles to account for 40% of global sales by 2024. With the improvement of automobile electrification, more and more electrical components and systems need to be isolated. For example, electric vehicles equipped with 400 V DC batteries are becoming more and more popular, which brings obvious security risks.

More electronic products need more isolation.

The challenges faced by the new generation of isolation solutions are increasing both in quantity and type. These systems, especially for isolated design, involve complex architectures and processes that limit agility and flexibility, but also hinder change. The acceleration of competition and globalization has forced enterprises to pay more attention to TTM and ROI. This means that the development team must execute the plan in a shorter time. With more and more rigorous review and demand for design and development resources, there is still a lack of experience in all key design areas. It takes a minimum number of iterations to achieve the return on investment goal, but at the same time, pressure from competitors will quickly and relentlessly push high-performance goals in order to make the product different. New regulatory bodies and stricter regulations require additional application testing and certification. The demand is increasing rapidly and the risk is very high.

Understanding isolation design

Although isolation is an important part of isolation design, it is not a simple design part.

From determining the required isolation level to providing isolation power to assist isolation of data paths to making solutions suitable for available space, many design tradeoffs need to be assessed. However, each new project has its own unique design objectives and design requirements. Many factors (including technical difficulty, similarity with previous designs, timing and resource allocation) together determine how many designs can be reused and how many new design options are needed. With very few changes, reusing previous design or architectural approaches often reduces risk and speeds up execution. However, the improvement of new functions or performance often determines the need for new methods. It is also important to use scarce development resources to evaluate new and improved technologies and to enhance the technical value of design.

Limitations of traditional methods

The emergence of integrated isolated DC-DC converter provides a compact and easy-to-use solution with documented security authentication, which makes the above considerations easier to solve. Suppose there is a scenario where a new project has been approved and the previous design needs to be upgraded to achieve higher performance targets and more versatility. Team members are energetic and ready to work. However, project technicians have to worry about all the factors that can go wrong, and the complexity of management is increasing under tighter budgetary and schedule constraints.

Meeting increasingly stringent electromagnetic compatibility (EMC) requirements is one of these project management challenges. More and more emerging applications and markets need to conform to many EMC specifications, and standards are constantly improving with more stringent performance constraints.

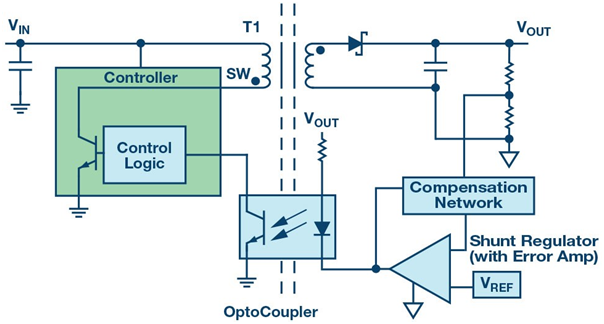

The existing discrete solutions, such as isolated flyback converters, have the advantages of low cost of bill of materials (BOM), but they also have some shortcomings. Typical flyback designs (Fig. 1) include controllers that drive isolation transformers, secondary rectifiers and filters, and optical isolation feedback networks. Error amplifier needs to develop compensation network design engineering to stabilize the voltage loop, and its performance also depends on the consistency of optical coupler performance. Photocouplers are often regarded as inexpensive isolators for power supply, but their current transfer ratio (CTR) variations limit the performance of voltage feedback and the range of effective operating temperature. CTR parameters are defined as the ratio of output transistor current to input LED current, and it is non-linear and has obvious individual differences. The initial CTR of optical couplers usually has a 2:1 uncertainty, which decreases by up to 50% after years of use in high-temperature environments (e.g. optical couplers in high-power, high-density power supplies). For project managers, the flyback device separation method seems to be better from a cost point of view, but it needs to weigh the amount of work and technical risks.

Fig. 1: typical isolated flyback DC/DC converter.

Another problem of the discrete method is whether it can meet the safety standards. Safety agencies are more and more rigorous in reviewing discrete design, so it is often necessary to design iterations to obtain the necessary certification for the design of discrete systems.

Isolation in the system also increases the complexity of power design. Typical non-isolation design has common constraints, such as input voltage and output voltage range, maximum load current, noise and ripple, transient performance, start-up characteristics, etc. Essentially, isolation barriers cannot easily monitor both input and output conditions, which makes it more difficult to achieve performance indicators. Dipole antennas are also formed in the partitioned contact area, and any common-mode current passing through the barrier excites the dipole and generates useless radiation energy.

Through testing

In order to make the discrete power design pass EMC authentication, it may take several iterations to complete it correctly. EMC testing is time-consuming and expensive, and teams need to spend hours preparing and monitoring tests by external EMC compliance agencies. Once the problem occurs, it is necessary to return to the laboratory for troubleshooting and modification. The design must then be fully re-characterized to ensure that the standard performance indicators are not affected by modifications. Next, go back to EMC to retest.

The final stage is to obtain the necessary safety certification. This is another lengthy and costly process, implemented by external security agencies. The design team must prepare a large number of documents and check them carefully. Any new design requires additional review, so reusing previously certified circuits is highly desirable. If the agency finds that the product does not meet the safety requirements, it may be necessary to modify the discrete isolated power supply design. Once modified, it will need to be redesigned and re tested through EMC.

Better solution

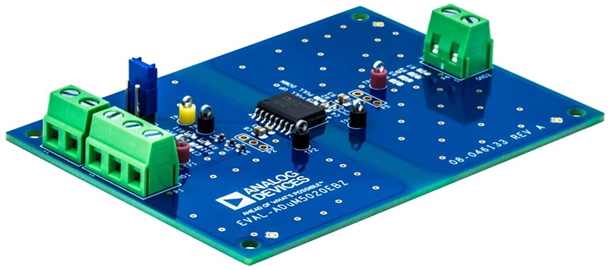

The answer to these problems is fully integrated, secure and certified components with EMC performance documentation. One example is the ADuM5020/ADuM5028 low radiation isolation DC-DC converter using isoPower technology. These products can provide up to 0.5W isolation power supply from 5V DC power supply, working temperature range from - 40 C to 125 C. They have been certified by UL, CSA and VDE, and meet multiple system and component Safety specifications. These products are used in simple double-layer printed circuit boards (pcb, Fig. 2) and can meet the CISPR 22/EN 55022B radiation requirements under full load conditions.

Figure 2: using ADuM5020, compact structure and simple layout.

Small packages (16-pin and 8-pin wide SOIC) occupy only a small PCB area and can meet radiation targets without safety capacitors. This makes isolated power supply circuits smaller and cheaper than discrete methods. For example, embedded splicing capacitors (in the discrete method) require four or more layers of pcb, and require customized intervals to generate the correct capacitors.

Increasing complexity by meeting more isolation needs

With the increasing trend of electrification of cars and other means of transport, the demand for isolation is also increasing. At the same time, fierce competition makes reducing costs and shortening the time to market is particularly necessary. Coexisting with these factors are stricter regulatory requirements and the inherent complexity of isolated design. Traditional isolation methods can not successfully cope with the integration of market demands and challenges. Fully integrated, secure and certified isolated DC-DC converter with EMC performance documentation provides a better solution for system designers. They can significantly reduce design complexity and ensure better EMC testing effectiveness and compliance. Because it takes less time to redesign, representationalize and retest, designers can focus more on how to reduce circuit board space, risk, cost and time to market.

English

English 中文

中文